Cavity Barriers

As most buildings contain a multitude of concealed cavities and voids within walls, floors, ceilings and roofs, effective cavity barriers are essential to restrict the spread of smoke or flames. If there is a fire, the intumescent material which makes up the barrier will expand, sealing off the gaps.

Key Features

Non-Combustible

Lightweight

Fast Track solution

Cost effective

Siderise

Siderise

FastFrame is an adjustable cladding fixing system that suits most brands of exterior cladding panels. We can offer a technical service to calculate the safest yet most cost-effective bracket spacings to support your facade. Save time and money with FastFrame get in contact today.

- Allows continuous ventilation and drainage behind external envelope

- Market leading fire resistance

- Rapid seal closure times

- Fully compliant and meets ASFP and CWCT guidelines

- Horizontal barriers can incorporate up to 50mm continuous ventilated air space

- Vertical barriers accommodate cladding movement during construction

- Free from Volatile Organic Compounds

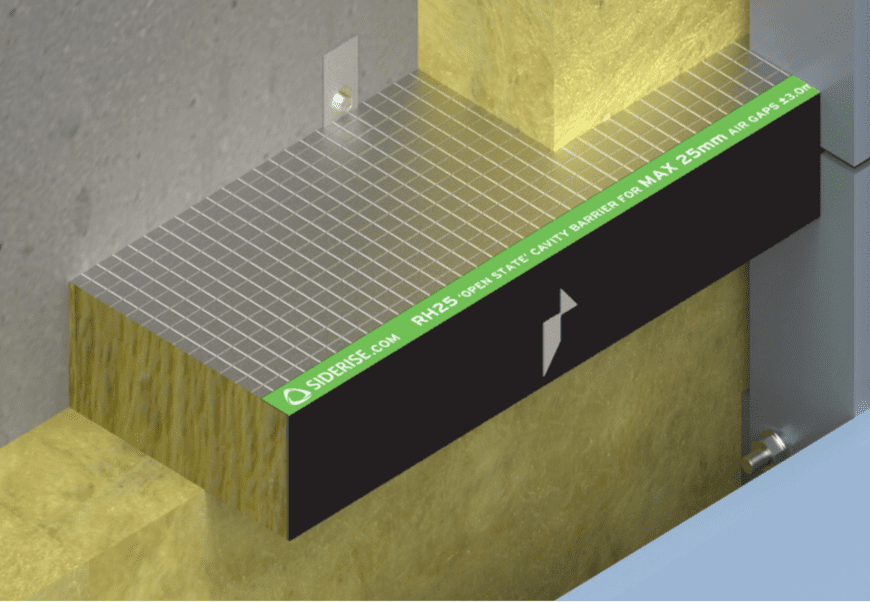

SIDERISE RH ‘Open State’ horizontal cavity barriers

SIDERISE RH ‘Open State’ horizontal cavity barriers have been specifically developed to meet the requirements for cavity barriers used in drained and ventilated facades. Their use ensures that the system will drain any moisture within the façade construction, whilst maintaining airflow and, in the event of fire, provide an effective hot smoke and fire seal. SIDERISE has developed two ‘Open State’ (open void) horizontal solutions: RH25(G/S) for air gaps up to 25mm and RH50(G/S) for air gaps up to 50mm. The product range is fully compliant to current market requirements and additionally has been tested to recent ASFP Guidance: ‘Open State’ Cavity Barrier used in External Envelope or Fabric of Buildings, utilising principles of EN 1363-1.

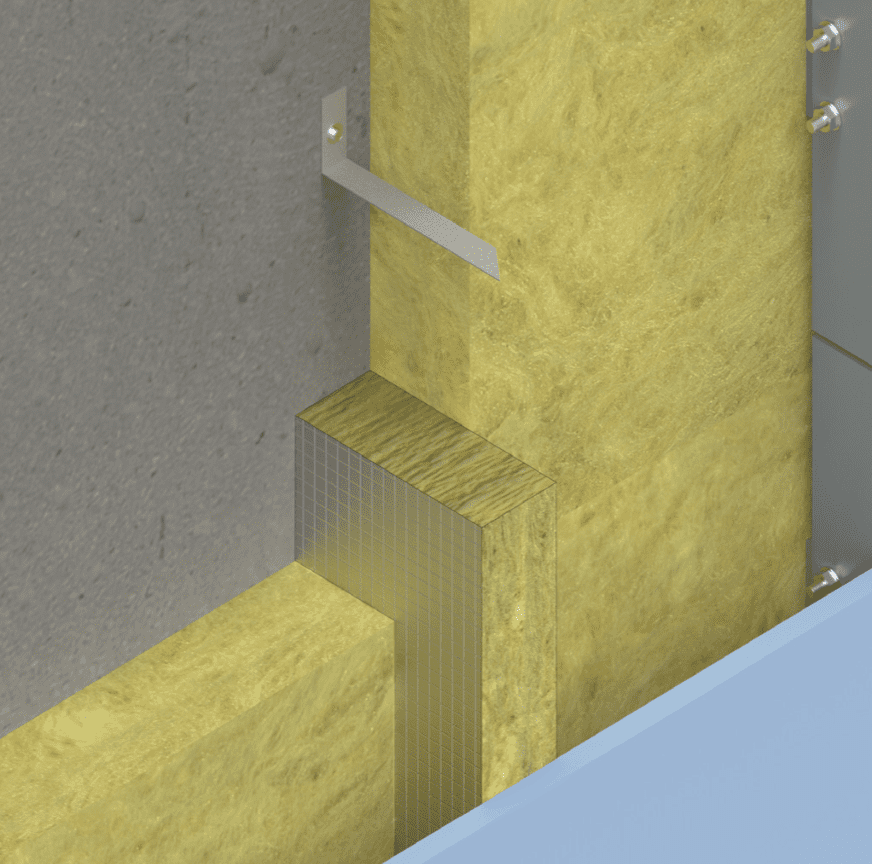

SIDERISE RV vertical cavity barriers

SIDERISE RV vertical cavity barriers for rainscreen cladding are used to full fill the void between the external envelope and internal structure. By fully sealing the void, they assist ventilated facades to Benefits function by maintaining air-pressurisation compartmentation. Importantly, their unique stonewool lamella core construction enables the vertical barriers to accommodate the serviceability movement normally associated with rainscreen facades. Intersections between horizontal and vertical cavity barriers are simply abutted.

FSI

Silverliner® Open State Cavity Barrier

Silverliner® Open State Cavity Barrier (OSCB) is developed to protect the voids between the outer façade and the inner construction element of the building. The product is designed for use in a ventilated façade, the Silverliner® OSCB allows for 25mm or 50mm linear air gap to ensure movement of air and drain any moisture within the facade. The aluminium foil restricts fibre migration and offers a class ‘0’ rating. In the event of a fire the intumescent outer edge of the product will expand and close the ventilation gap between the product and the façade preventing the passage of fire and smoke from one compartment to another.

Key Advantages

- 3rd Party approved- IFCC- IFCC 1672

- Assumed working life of 25 years

- Non-combustible core

- ‘Dry fit’ solution, no cure time

- Fast installation using brackets

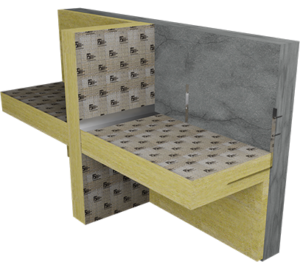

Paraflam®

Paraflam® is a perimeter fire stop designed for curtain walling and cavity barrier external rainscreen facades. Paraflam® is a non-combustible stone wool based product with a foil facing which prevents fibre migration and provides an excellent seal. It is designed to reinstate the fire resistance of a compartment, as well as offering good thermal and acoustic performance.

Key Advantages

- Dry fit (no cure time required)

- Easy friction fit system

- High speed installation

- Non-combustible

- Lightweight

- Testing in voids up to 590mm

- Provides smoke seal

- Minimal waste

- Excellent acoustic performance

TENMAT

VFB Plus Ventilated Fire Barrier

Tenmat’s VFB Plus Ventilated Fire Barriers are ’open state’ cavity fire barriers for ventilated cavities of up to 450mm.

Each VFB Plus consists of a specially formulated fire rated stone mineral wool section with an integral high expansion intumescent seal fixed to the leading edge.The VFB Plus then leaves a maximum 44mm air gap to allow for drainage and maintain ventilation in normal use.

In a fire situation the intumescent seal rapidly expands to seal off the air gap and prevent vertical fire spread within the external wall.The product has undergone extensive fire testing following the principles of BS EN1363-1 and in accordance with ASFP TGD19 (Fire Resistance Test for ‘Open- State’ Cavity Barriers).

The VFB Plus are mechanically fixed horizontally within ventilated cavities behind the external wall substrate following the fire compartment line.

- Typical Fire Ratings of minimum 30 to 60 minutes Integrity and Insulation

- Higher Fire Ratings available dependent on application

- Maintains a 44mm air gap

- Up to 450mm cavities tested

- Standard thickness of 75mm

- Durability and Age Tested

- Fixing brackets included as standard

VFB 120/120 Ventilated Fire Barrier

Tenmat’s VFB 120/120 Ventilated Fire Barriers are ’open state’ cavity fire barriers for ventilated cavities of up to 450mm. Each VFB 120/120 consists of a specially formulated fire rated stone mineral wool section with an integral high expansion intumescent seal fixed to the leading edge.

The VFB 120/120 then leaves a maximum 25mm air gap to allow for drainage and maintain ventilation in normal use. In a fire situation the intumescent seal rapidly expands to seal off the air gap and prevent vertical fire spread within the external wall.

The products have undergone extensive fire testing following the principles of BS EN1363-1 and in accordance with ASFP TGD19 (Fire Resistance Test for ‘Open- State’ Cavity Barriers).

- Fire Ratings of 120 Minutes Integrity and Insulation for up to 300mm cavities

- Fire Ratings of 90 Minutes Integrity and Insulation for 300mm-450mm cavities

- Maintains a 25mm air gap

- Up to 450mm cavities tested

- Standard thickness of 75mm

- Durability and Age Tested

- Fixing brackets included as standard