Terracotta

Terracotta cladding is continually evolving from the 90s technology of 600 x 300 red tiles to now versatile and bespoke glazes, shapes and solutions.

Modern manufacturing and glazing now gives architects and clients a new dimension when designing their buildings.

Whether oriented vertically, horizontally, shaped profiled, glazed or unglazed Terracotta offers endless configurations and finishes. As a natural solution for cladding it outperforms other alternatives whilst offering the potential to add distinction, warmth and uniqueness to buildings.

RGB Facades work closely with all parties from start to finish to make sure the project is as per the architect’s impressions and within the contractors budget.

Key Features

Non-Combustible

CWCT testing

Fast Track construction

Lightweight

Allows for thermal and movement

Cost effective

Varied size options

Universal sub structure

FACE – System Information

FACE

The FACE system is a rainscreen cladding solution made from natural terracotta, offering both modular and fully customised options.With tile thicknesses ranging from 20 mm to 100 mm, and profiles available in smooth, ribbed, grooved or even wavy formats, the system offers exceptional architectural freedom. First launched in 2004, FACE has featured on prominent projects worldwide, delivering a contemporary aesthetic, technical performance, and environmental integrity.

Advantages of FACE:

- Wide variety of standard and custom formats

- Suitable for vertical and horizontal installation

- Durable, low-maintenance, non-combustible

- Can be tailored to specific project requirements

- High-performance fixing system with stainless steel and aluminium

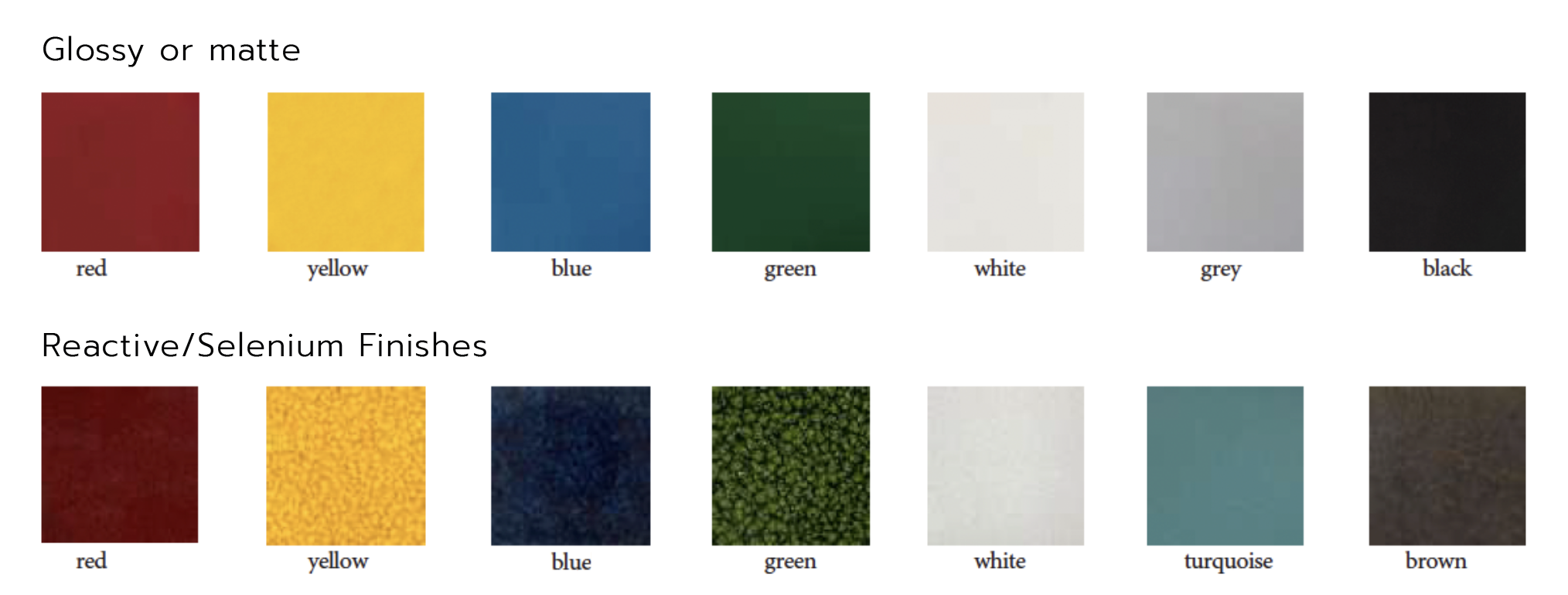

- Available in smooth, textured, glazed, and reactive finishes

- Natural shade variations for organic facade effects

NBK- System Information

NBK

All NBK® terracotta products are manufactured with state-of-the-art firing techniques and production methods. Carefully selected pure clay provides raw material with the highest mechanical properties and structural behavior. NBK offers a wide variety of standard colors, textures and glazes as well as endless customization possibilities. NBK terracotta products minimize life-cycle environmental impacts while improving a building’s overall comfort and health and are 100% recyclable.

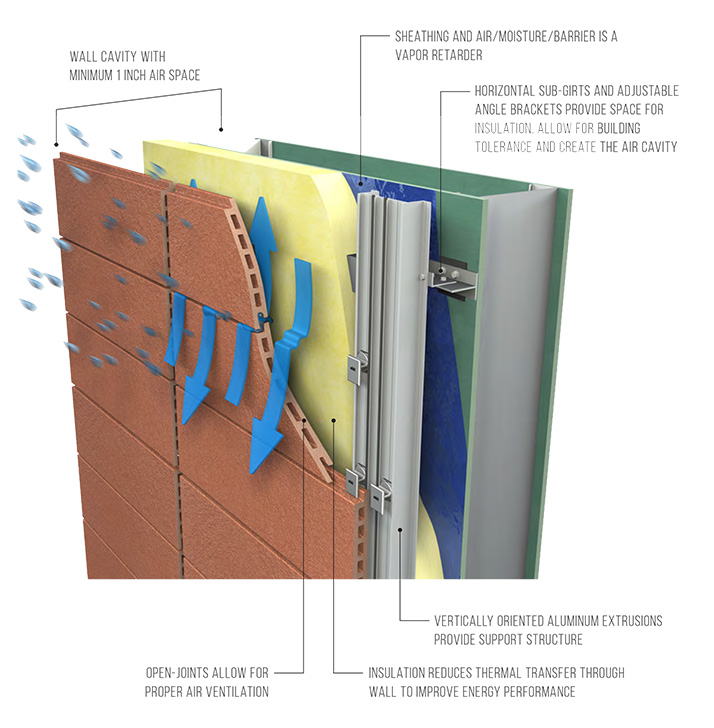

The NBK® TERRARTTM façade system is specially designed and engineered for use as a rainscreen system.

The design allows for air to flow through open joints to balance air pressure and minimise water penetration. Back ventilation assists in maintaining a dry cavity and negates the build up of hot air.

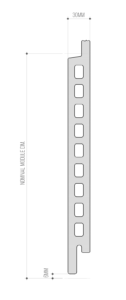

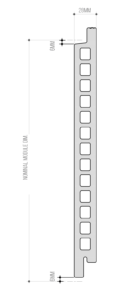

Terrart Large

- Support high wind-load pressures and long spans

- Ideal for custom profiled elements

- Often used for high rise buildings

- Best for impact resistance requirements

Typical Maximum Dimensions (Larger Sizes Available on Request)

- Length: 6’-0” (1829mm)

- Height: 2’-11” (899mm)

- Thickness: 33-40mm

- Mass per unit area: 12 lbs./sq.ft.

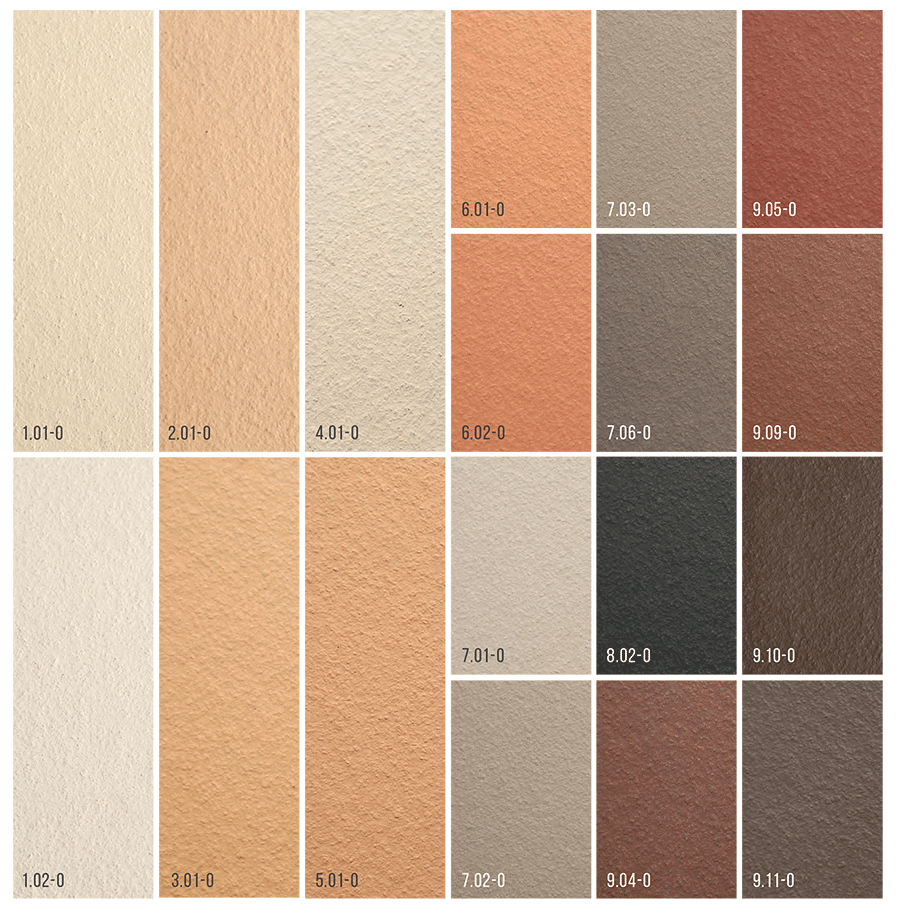

Textures & Finishes

Reduction Fired

NBK’s Reduction Firing technique reduces oxygen in the firing process to give terracotta tiles a unique metallic appearance. The metallic expression of Reduction Fired tiles varies depending upon the light, much like their metal counterparts, while retaining the durability and weather resistant qualities of terracotta. Diverse metallic colors, from gray tones to deep red hues, create color variation and visually contrasting facades.

Glazes and Engobes

Glaze finishes, available in different gloss levels from matte to high gloss as well as a broad range of colors, create lively and unique facade designs. Glazes are single or double fired. Double firing increases color options and allows for glazed edges. Engobe finishes also provide additional color options for facades. This cost-effective solution, available in matte and semi-gloss, features white or colored slip-clay coating applied to the clay body to impart colors or textures. All glaze and engobe finishes are durable and add to overall resiliency against the elements.